Stainless steel grade AISI 304 that “Wellmer” products are made from is durable and rust-proof material. Service life of stainless steel may last for decades, but there is a set of unfavorable conditions that may shorten the service life of steel.

As the hot water towel dryer is connected to a heating system (or DHW supply) the water quality is of high priority for its operation. High oxygen and mineral matter concentration in water negatively affects the steel structure. However stray-current poses the major hazard for the dryer surface. Proper grounding of the towel dryer allows eliminating the major reason of stainless steel corrosion – the occurrence of overcharge.

Let us find out what electrochemical corrosion is and where does stray-current come from?

Reasons of occurrence of stray-current corrosion

It is assumed that alloyed steel is corrosion proof. This is indeed the case. But under certain conditions anticorrosion properties of the stainless steel weaken. Presence of air particles in the water may in no way harm the stainless steel pipe, on the contrary, chromium oxide is a primary element of rust protection – it appears on the surface of stainless steel exactly by means of a contact with oxygen-enriched environment. But if an electric charge is “attached” to oxygen – electrochemical reaction is inevitable.

Steelwork below ground is subject to two types of corrosion – galvanic and stray-current corrosion. Galvanic reaction occurs between two incompatible materials. This type of interchange between more constant and more active metal happens by means of potential difference. Usually more active alloy is disintegrated. Example of galvanic corrosion is stainless steel failure at contact with ferrous materials or aluminum. Electrochemical reaction likewise is a result of different electric potentials, i.e. some sort of galvanic impact enhanced by presence of electric charge.

The following reasons for occurrence of stray-current are distinguished:

- absence or improper formation of an earth loop;

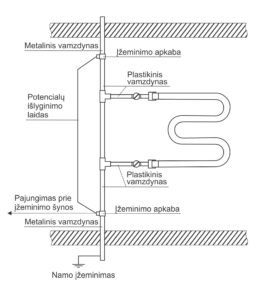

- replacement of metal pipes of the water riser with reinforced-plastic pipes without successive grounding (conductor circuit break);

- vicinity to electrified tracks (tram lines, railways) that are being improperly serviced;

- accidental dissipation of current from electrically-conductive lines.

Excess electric charges may be avoided by means of duly formed and integral ground contact.

Earth loop – how to form it

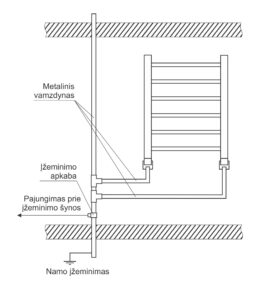

According to building regulations all metallic elements shall be grounded without failure. New buildings employ an equipotential bonding system, older buildings feature metal pipes supply to general earth loop (in the basement). Connection of the hot water towel dryer may affect equipotential bonding system (EBS). To ensure reliable protection of the towel dryer from stray-current, it is enough to connect all metal devices in the bathroom with the metal water riser.

Installation of a grounding-type receptacle completely solves the problem of occurrence of electric charges of the electric towel dryer. The question remains – how to ground the water towel dryer?

Instruction manual of hot water towel dryer includes:

- conjunction of all metallic elements of the bathroom into one network – by copper conductor with a section from 4 mm2;

- conductor and main conductor cable are connected at the junction box by means of bonding installation;

- the ground cable is attached on the towel dryer or inlet piping by an earth tag.

Earth tag is a metal tie with terminal block, the main purpose of which is to transfer the spontaneously occurring potential to the groundwire. The earth tag prevents device failure on which it is mounted on and also protects a person from electric shock. Protective screed is installed on steel or copper pipes.

Signs of electrocorrosion

At the early stage of electrochemical damage the residue may be observed on the pipe surface similar to scale crust or brownish scurf resembling rust. Usual spots of pitting corrosion development on the towel dryer are seams and attaching points of bonding strips. Staining appearing on the towel dryer is the first indication of metallic wear. If no measures are taken, the through-hole may develop. In this case the towel dryer becomes unserviceable due to heavy damages.

Electrochemical type corrosion prevention methods:

1) Inspection of the earth loop, reconstruction of its integrity.

It is impossible to independently distinguish the presence of stray-current and malfunctions of the earth loop. With the help of an oscillograph the electrician may identify the problem and offer a solution.

2) Inspection of the earth loop, reconstruction of its integrity.

It is impossible to independently distinguish the presence of stray-current and malfunctions of the earth loop. With the help of an oscillograph the electrician may identify the problem and offer a solution.